- Cookie Settings

- +49 (0)7223 9126800

- support@bailaho.net

STOOSS is engaged in highly developed thermo-forming technology of unalloyed, low and high-alloy steels, light and non-ferrous metals and nickel alloys.

Seamless profiled rolled rings, balls and all types of open-die forgings – forged in the contour – and weighing up to about five tons are typical STOOSS specialities.

Our Strengths

|

|

Production

Apart from high productivity and precision, STOOSS FORGEMASTER’s prime concern is fast production, individually tailored to customer’s needs, so that the smallest series – as also the industrial-scale production – can be manufactured economically. Many years of experience enabled us to develop processes – some controlled electronically, some manually – which guarantee precision and accuracy from the first to the final step. The annual forging capacity is approximately twenty thousand tons.

Products

Ring Mills

Ring Mills

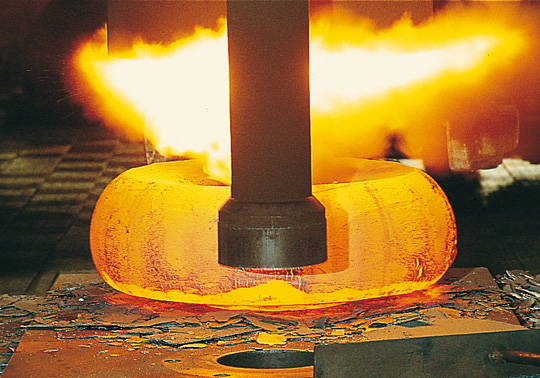

The production of seamless hot rolled and profiled rings weighing up to approx. 5 tons are typical STOOSS specialities.

In the production of rings, the billets are preformed, punched and then rolled to the required dimensions on ring rolling mills.

Open-die Forging

Open-die Forging

STOOSS is extraordinarily competent also for heavy individual items or small quantities of large parts.

Our open-die forging facility produces parts for turbines, gears, valves or machines from 100 kg up to 5 tons.

Hammer-Forging

Hammer-Forging

Individually forged parts are no problem at our hammer forging facility.

With extraordinary skill, we forge bars, shafts and rings which regularly weigh 30 to 60 kilograms.

Production Facilities

A 2‘700-ton forging press and a powerful ring rolling mill, both electronically controlled, are the focus of resourceefficient production today. The latest heat treatment equipment and CNC processing machines complete the company‘s state-of-the-art plant.

Heat Treatment

The heat treatment appropriate for the material optimises the physical properties of the forged parts. Using accurately controlled heat treatment, the physical properties meet our customers‘ requirements or standard specifications.

STOOSS operates with environmentally compatible natural gas and electrically powered heat treatment furnaces which are calibrated regularly. The parts are quenched in oil, water or polymer.

Up-to-date measurement and control instruments record the specific heat treatments such as normalizing, annealing, tempering or soft annealing appropriate for each material.

Machining

The cost-cutting reduction of the mechanical processing time is a great advantage for our customers. Our trained specialists shape each forging in rational single or series production accurately according to the customers‘ requirements, using modern machines, conventional and CNC center lathes, CNC vertical lathes, boring mills or milling machines. In addition, special processing such as flame cutting is used and the forgings can also be shot blasted at STOOSS.

Vacant Jobs

Company SCHMIEDEWERK STOOSS AG from 8908 Hedingen Bailaho: The company SCHMIEDEWERK STOOSS AG offers products and services like Forgings, Forgemaster, Open-Die Forgings, Seamless Hot Rolled Forgings und Steels. Send an inquiry o this company to set the first steps in a business contact. Please let the company know that you found them on Bailaho.

Monday : 08:00 - 17:00

Tuesday : 08:00 - 17:00

Wednesday : 08:00 - 17:00

Thursday : 08:00 - 17:00

Friday : 08:00 - 17:00

Scan the QR code to call up the company profile on your smartphone.