- Cookie Settings

- +49 (0)7223 9126800

- support@bailaho.net

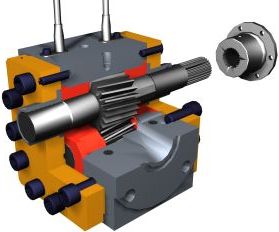

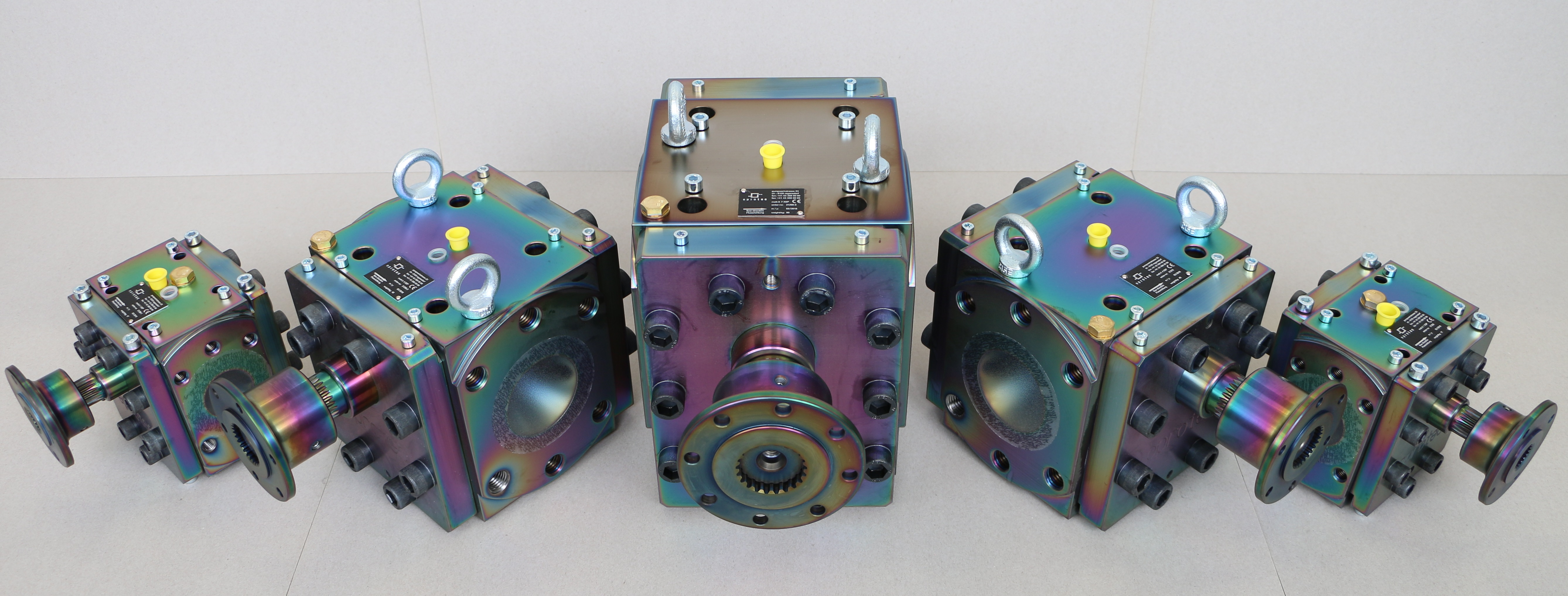

eprotec, the specialist for enamel and gear pumps, In the year 2000 optimized the diameter of its gear melt pumps.

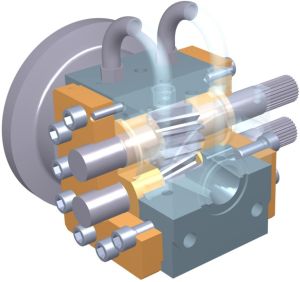

The following advantages result from this; Volume reduction and thus a higher flow rate and shorter residence time! The eprotec melt-X gear pump series with its dead zone-free, rheologically optimized flow geometries guarantees minimum product residence times, uniform flow velocities without wall adhesion or discoloration of the melt.

Especially well suited for frequent color changes or product changes.

The filling and squeezing grooves of the eprotec plain bearings are perfectly matched to the interventions of the teeth,

Tooth base to head from the mating wheel. This will be the most gentle and complete

Squeezing reached. So the slightest shearing and friction is produced and the best

Self-cleaning achieved. That's the unique thing about the eprotec melt-X.

eprotec offers comprehensive advice, services and spare parts for gear pumps in polymer processing extrusion, thermoplastic processing. Take advantage of our leading know-how for the products melt-X, elast-X and m-pac! In addition, we also offer our services and spare parts for the gear pumps of other manufacturers. This includes:

|  |

|

Engineer (m/w/d)

Company eprotec extrusion technology AG from 8105 Regensdorf Bailaho: The company eprotec extrusion technology AG offers products and services like Pump, Gear pumps, Gear, Pump technology und Gear pump. Send an inquiry o this company to set the first steps in a business contact. Please let the company know that you found them on Bailaho.

Monday : 08:00 - 17:00

Tuesday : 08:00 - 17:00

Wednesday : 08:00 - 17:00

Thursday : 08:00 - 17:00

Friday : 08:00 - 17:00

Scan the QR code to call up the company profile on your smartphone.